Catheter Contract Manufacturing and Design

Catheter Contract Manufacturing and Design. Complex catheters including: EP electrophysiology, balloon, steerable, ablation catheters.

In the high-stakes world of medical device development, the leap from a "napkin sketch" to a life-saving tool is often fraught with technical hurdles. For complex interventional procedures—ranging from cardiac mapping to neurovascular access—the catheter is the unsung hero.

At the heart of this innovation is Prevailing Medical, a contract engineering and manufacturing powerhouse based in Plymouth, Minnesota. Specializing in high-grade, complex catheters, they have become a go-to partner for both agile startups and established medical giants. Here is a look at how they are redefining catheter design and manufacturing.

1. Concept to Commercialization: The Design Philosophy

Prevailing Medical doesn't just build to print; they design for the real world. Their approach centers on Design for Manufacturability (DFM), ensuring that a brilliant engineering concept can actually be produced at scale without sacrificing quality or breaking the bank.

Key Specialized Catheter Types:

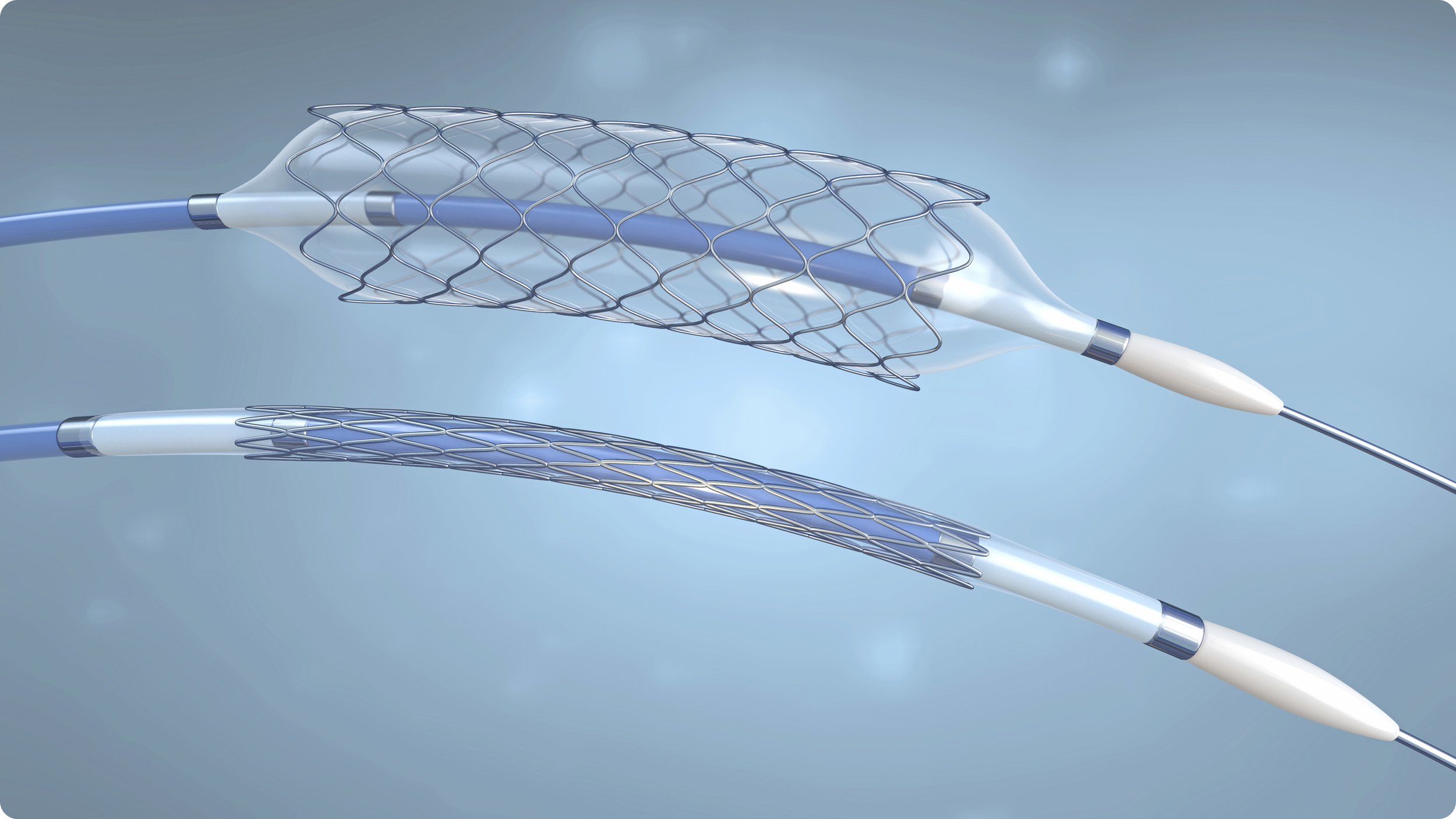

Steerable & Robotic Catheters: Precision-engineered for navigating the most tortuous pathways of the human anatomy.

Sensor-Integrated Systems: "Smart" catheters that provide real-time data.

Balloon & Valve Delivery Systems: Essential for TAVR (Transcatheter Aortic Valve Replacement) and other structural heart interventions.

Electrophysiology (EP) & Mapping: Specialized devices used to diagnose and treat cardiac arrhythmias.

2. Advanced Manufacturing Capabilities

Manufacturing a device that must be both flexible enough to travel through a vein and rigid enough to transmit torque requires extreme technical precision. Prevailing Medical utilizes a 24,000 sq. ft. facility, featuring a 2,500 sq. ft. ISO Class 7/8 certified cleanroom.

Core Technical Competencies:

Precision Extrusion: They specialize in quick-turn extrusions (sometimes as fast as 24-72 hours), including single-lumen and complex multi-lumen tubing using materials like Pebax, Nylon, and Polyurethane.

Micro-Assembly & Bonding: Utilizing laser welding, UV bonding, and hot jaw bonding to join disparate materials—like nitinol reinforcements to polymer shafts—with seamless transitions.

Braiding & Coiling: Adding stainless steel or nitinol layers to enhance kink resistance and column strength, ensuring the catheter doesn't collapse during use.

Catheter Tipping & Shaping: Custom tip forming to create atraumatic ends that protect delicate vessel walls.

3. The "Medical Alley" Advantage

Location matters. Being situated in Minnesota’s "Medical Alley"—a global hub for healthcare innovation—allows Prevailing Medical to tap into a rich ecosystem of specialized vendors and top-tier engineering talent. This geographic advantage translates to faster problem-solving and a deeper understanding of current FDA and ISO 13485 regulatory standards.